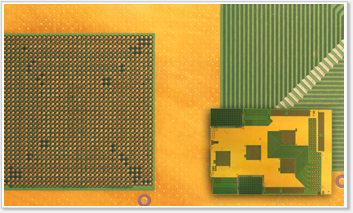

PRINTED CIRCUIT BOARD TECHNOLOGY

Metaplast Circuits specializes in prototype and mid-volume printed circuit board production, using a diversified range of materials and technologies. We have manufactured an outstanding range of products and received many approvals with both Hi-Rel / Military and Commercial clients. We are the leaders in printed circuit board manufacturing of “exotic” materials and mixed laminate packages.

Technology Focus

Our strategy is to focus on a wealth of diversified materials management and technologies. As technology is accelerating, we have focused on providing our customers solutions for:

- Mixed (hybrid builds) and exotic materials

- Finer geometries

- Higher layer counts

- Complex Structures

- Signal integrity

- Higher density

- MicroVia

- Multiple Stack-up of Blind & Buried Vias for Sequential Laminations

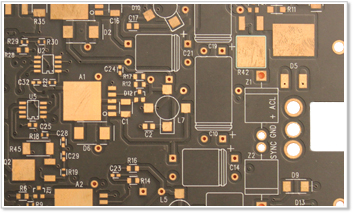

Technology Profile

With the use of reverse pulse copper plating, and dual rectification DC copper plating, we realize superior plating distribution, which is necessary for very small holes and blind vias. We have produced up to 42 layers on 25” x 26” panel, with 15:1 aspect ratio in a .140” thick board.

Process capabilities include:

- Solder mask over bare copper

- Blind and buried vias

- Plated edges

- Heatsink fab and bond

- Line and space to .003” (.002″ possible)

- Mixed laminates & Hybrids

- Controlled Impedance

- PTFE, Teflon & Ceramic processing

- Conductive & Non-Conductive Hole Fill & Planarization

- Profile Milling & Side-Tapping

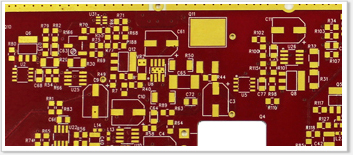

Time Critical Focus

- We specialize in servicing 24 hr to 3 day turnarounds

- Quick turn-around, low to mid-volume printed circuit board production with a diversified range of materials

- Our extensive capability allows us to provide you with printed circuit board solutions to all your leading-edge technology needs